Using OpenSCAD to build custom 3D pieces Build Your Own Body

Tutorials – OpenSCAD

OpenSCAD lets you use simple scripts to build 3D bodies from primitive shapes that you can then send to your 3D printer. It also lets you create custom shapes for pieces and objects. In this article, we look at two ways to do just that.

In last month's installment [1], you saw how to use primitive 3D bodies (cubes, spheres, cylinders, etc.) to build complex 3D objects. Apart from combining basic primitives, there are more ways of making bodies in OpenSCAD [2]. One is to extrude them from 2D shapes; another is to build them from a bunch of vertices and faces you define in arrays.

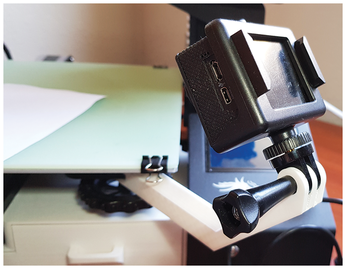

Let's see how both of these work by building an "arm" that will let you attach a sports camera to a printer's hotbed. This arm could look something like what you can see in Figure 1. With the arm attached to the bed, you will be able to monitor your print with the action always in the center of the frame.

[...]

Buy this article as PDF

(incl. VAT)

Buy Linux Magazine

Subscribe to our Linux Newsletters

Find Linux and Open Source Jobs

Subscribe to our ADMIN Newsletters

Support Our Work

Linux Magazine content is made possible with support from readers like you. Please consider contributing when you’ve found an article to be beneficial.

News

-

Introducing matrixOS, an Immutable Gentoo-Based Linux Distro

It was only a matter of time before a developer decided one of the most challenging Linux distributions needed to be immutable.

-

Chaos Comes to KDE in KaOS

KaOS devs are making a major change to the distribution, and it all comes down to one system.

-

New Linux Botnet Discovered

The SSHStalker botnet uses IRC C2 to control systems via legacy Linux kernel exploits.

-

The Next Linux Kernel Turns 7.0

Linus Torvalds has announced that after Linux kernel 6.19, we'll finally reach the 7.0 iteration stage.

-

Linux From Scratch Drops SysVinit Support

LFS will no longer support SysVinit.

-

LibreOffice 26.2 Now Available

With new features, improvements, and bug fixes, LibreOffice 26.2 delivers a modern, polished office suite without compromise.

-

Linux Kernel Project Releases Project Continuity Document

What happens to Linux when there's no Linus? It's a question many of us have asked over the years, and it seems it's also on the minds of the Linux kernel project.

-

Mecha Systems Introduces Linux Handheld

Mecha Systems has revealed its Mecha Comet, a new handheld computer powered by – you guessed it – Linux.

-

MX Linux 25.1 Features Dual Init System ISO

The latest release of MX Linux caters to lovers of two different init systems and even offers instructions on how to transition.

-

Photoshop on Linux?

A developer has patched Wine so that it'll run specific versions of Photoshop that depend on Adobe Creative Cloud.