Getting started with the Ender 5 Pro 3D printer

Get Printing

Just unpack and get started? It's not so easy with hobby 3D printing.

Whether it's decorative elements for a new case-modding project, custom trees to add a flourish to the Gloomhaven board game, or homemade gears for quirky gadgets, 3D printers make craft projects much easier – or so I thought. I had been struggling with my conscience for a long time about buying a 3D printer and weighing the arguments. Do I really need this? Isn't there a lot of work involved? Could I maybe invest the money in a better way?

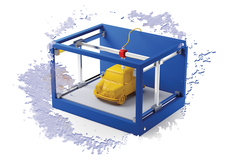

Eventually, I gave in to my cravings when Chinese manufacturer Creality3D offered the Ender 5 Pro [1] for just EUR350 (~$414). Two weeks later, the package reached my home. After I unpacked, one of my first fears disappeared. I thought the DIY assembly would be complicated, but it was actually relatively easy (Figure 1). However, I soon discovered that the initial assembly was only the beginning of my quest. Of course, this story is only about one man and one 3D printer model, but many of the issues I faced are similar to problems you might see with other hobby printers. This article is intended as a practical case study on what it takes to get a 3D printer assembled and working in the real world.

Successful Build

The Ender 5 Pro arrives with some pre-assembled parts. You won't need to assemble the printing bed, the extruder, or the microcontroller (including the display). An easily understandable set of build instructions and the right tools for the bolting work are also included, and everything is packaged between soft foam pads.

[...]

Buy this article as PDF

(incl. VAT)

Buy Linux Magazine

Subscribe to our Linux Newsletters

Find Linux and Open Source Jobs

Subscribe to our ADMIN Newsletters

Support Our Work

Linux Magazine content is made possible with support from readers like you. Please consider contributing when you’ve found an article to be beneficial.

News

-

Introducing matrixOS, an Immutable Gentoo-Based Linux Distro

It was only a matter of time before a developer decided one of the most challenging Linux distributions needed to be immutable.

-

Chaos Comes to KDE in KaOS

KaOS devs are making a major change to the distribution, and it all comes down to one system.

-

New Linux Botnet Discovered

The SSHStalker botnet uses IRC C2 to control systems via legacy Linux kernel exploits.

-

The Next Linux Kernel Turns 7.0

Linus Torvalds has announced that after Linux kernel 6.19, we'll finally reach the 7.0 iteration stage.

-

Linux From Scratch Drops SysVinit Support

LFS will no longer support SysVinit.

-

LibreOffice 26.2 Now Available

With new features, improvements, and bug fixes, LibreOffice 26.2 delivers a modern, polished office suite without compromise.

-

Linux Kernel Project Releases Project Continuity Document

What happens to Linux when there's no Linus? It's a question many of us have asked over the years, and it seems it's also on the minds of the Linux kernel project.

-

Mecha Systems Introduces Linux Handheld

Mecha Systems has revealed its Mecha Comet, a new handheld computer powered by – you guessed it – Linux.

-

MX Linux 25.1 Features Dual Init System ISO

The latest release of MX Linux caters to lovers of two different init systems and even offers instructions on how to transition.

-

Photoshop on Linux?

A developer has patched Wine so that it'll run specific versions of Photoshop that depend on Adobe Creative Cloud.